Choosing a Reliable Banana Rollers Supplier for Custom Industrial Needs

Selecting a reliable Banana Roller supplier is a key decision for manufacturers who rely on consistent, durable, and customizable components for their production lines. Banana rollers play a critical role in various industrial applications, particularly in web guiding systems, tension control, and wrinkle removal during the processing of flexible materials like plastic film, paper, foil, textiles, and more. As demand for customized rollers increases, the focus has shifted to finding suppliers who can deliver precision-engineered solutions tailored to specific operational needs.

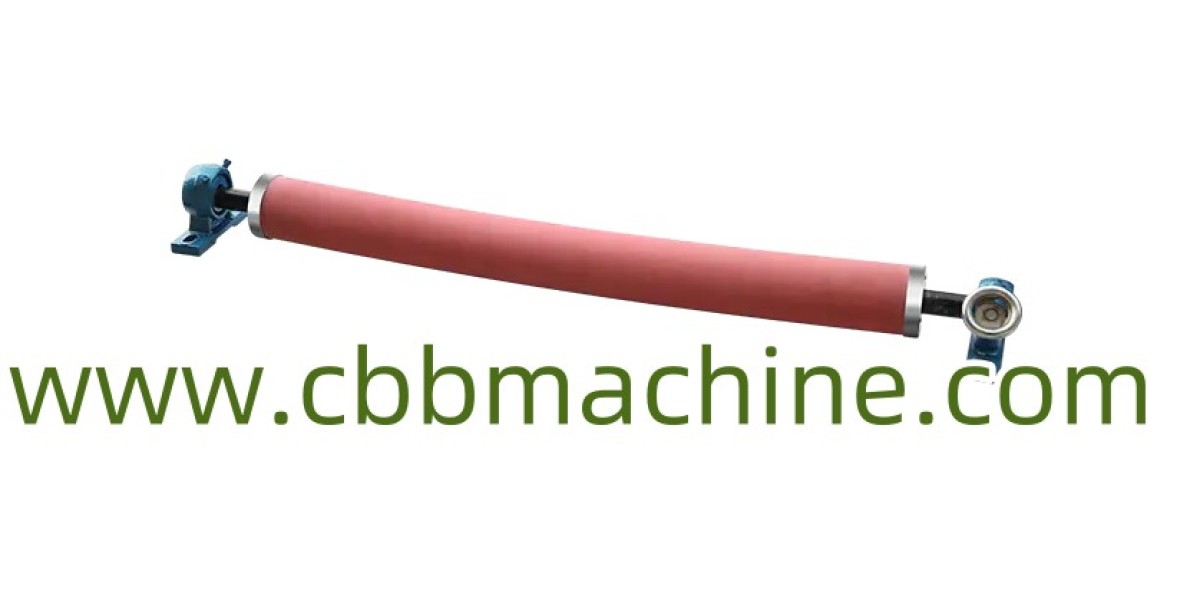

Banana rollers, also known as bowed rollers or spreader rollers, are designed to eliminate wrinkles and maintain tension uniformity across wide web materials. They are commonly used in printing, laminating, coating, slitting, and packaging processes. The effectiveness of these rollers depends on the bow angle, material type, and mounting configuration, all of which must align with the specific machinery and material being processed.

One of the major benefits of working with a specialized Banana Rollers supplier is the ability to customize roller dimensions and specifications. Depending on the application, a roller may require different bow angles, diameters, shaft types, coatings, or mounting options. For instance, in high-speed printing or slitting processes, a roller with minimal deflection and high-speed balancing is essential to ensure smooth and accurate web movement. Suppliers that understand these requirements are able to manufacture rollers that enhance both productivity and product quality.

Another factor to consider is the type of surface finish or covering used on the roller. Some applications require anti-static properties, while others benefit from wear-resistant or rubber-coated surfaces to improve grip and durability. An experienced supplier will offer a range of finishes, along with guidance on selecting the most suitable option for each production environment. Moreover, the choice of core material—often aluminum, stainless steel, or carbon steel—affects both the weight and corrosion resistance of the roller, which is crucial in humidity-prone or chemically active environments.

Maintenance and longevity are also important considerations. A high-quality banana roller should operate smoothly for long durations with minimal wear and vibration. This is achieved through precision balancing, quality bearings, and proper alignment during installation. Choosing a Banana Rollers supplier who emphasizes long-term performance and provides maintenance support can reduce production downtime and minimize replacement costs over time.

In many production facilities, space and alignment constraints call for specific roller configurations. Some processes may require reverse bowing, dual-end drive mechanisms, or adjustable bow angles to accommodate changing material properties or line speeds. A knowledgeable supplier can work closely with production managers and engineers to design and fabricate rollers that seamlessly integrate into existing systems, without disrupting current workflows.

Sustainability and energy efficiency are increasingly relevant in industrial equipment sourcing. Lightweight banana rollers made from aluminum or composite materials can reduce load on motors and bearings, contributing to more energy-efficient operation. In addition, rollers with low-friction bearings and well-engineered balance can improve machine performance while reducing noise and mechanical stress.

Communication and technical support are often overlooked aspects when sourcing industrial components. However, a supplier who is responsive and knowledgeable can make a significant difference during product specification, installation, and operation. Clear documentation, CAD drawings, and training resources ensure that every roller performs as intended and integrates seamlessly with existing machinery.

In conclusion, the selection of a dependable Banana Rollers supplier goes beyond simply purchasing a part—it is an investment in process reliability, product quality, and long-term efficiency. By focusing on suppliers who offer customization, technical support, quality assurance, and a clear understanding of industry-specific needs, manufacturers can enhance their operations and ensure consistent production outcomes.