The Role of Customizable Banana Rollers in Web Handling Systems

When it comes to web handling systems, maintaining the integrity of the material as it passes through various processes is paramount. Whether in the textile, paper, or packaging industries, ensuring that the material remains wrinkle-free and aligned is essential for both quality and efficiency. This is where customizable banana rollers come into play. As an essential component in many industrial operations, banana rollers are critical for effective web guiding and tension control. If you are looking for a reliable Banana Roller Supplier , understanding the various benefits and considerations of these rollers can help you make an informed decision.

What is a Banana Roller?

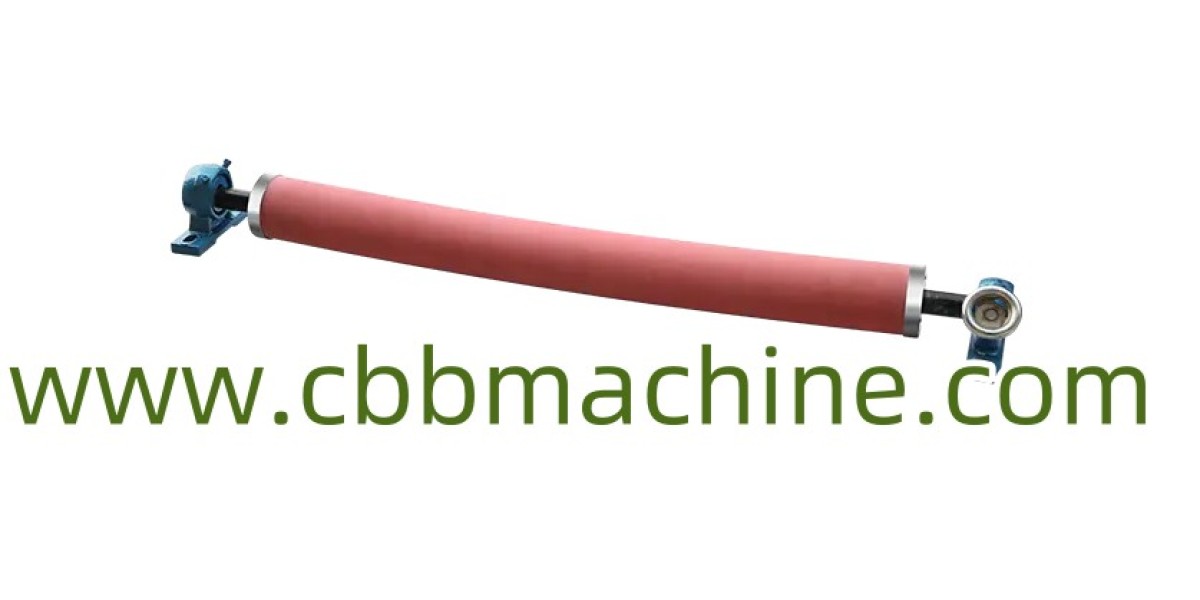

A banana roller, also known as a bowed roller, is a specialized piece of equipment that plays a key role in web handling systems. The roller is designed with a curved or bowed shape that allows it to apply consistent lateral tension to the web. As the material passes over the roller, the tension is distributed evenly, preventing wrinkles, folds, or misalignment that could affect production.

The banana roller gets its name from its shape – much like a banana, the roller is curved, which helps ensure the material stays flat and aligned. This unique design is critical in applications where precision and smoothness are key.

Customization for Specific Needs

One of the key advantages of working with a Banana Roller Supplier is the ability to customize the roller to suit the specific requirements of your production process. Not all web handling systems are the same, and the material being processed can greatly affect the type of roller needed.

For example, the diameter and width of the roller, the degree of curvature (or bow), and the surface material of the roller all contribute to the roller’s overall performance. Additionally, many suppliers offer different coatings, such as chrome or rubber, to suit various materials like plastic films, paper, textiles, or metal foils. Some applications may even require specialized features, such as adjustable tension controls or anti-static properties.

Benefits of Customizable Banana Rollers

Enhanced Web Tension Control

Banana rollers are designed to ensure uniform tension distribution across the width of the material. Customization ensures that the roller's curvature and surface properties match the specific material being processed, thereby preventing uneven tension that can lead to defects.

Improved Alignment and Flatness

One of the most common issues in web handling is misalignment, which can lead to wrinkles or uneven processing. Custom banana rollers ensure that the material remains flat and aligned, improving overall production efficiency.

Minimized Downtime

By working with an experienced Banana Roller Supplier, you can ensure that the roller is properly tailored to your needs, reducing the risk of malfunctions and downtime caused by equipment failure. Customization also helps improve the roller’s lifespan, resulting in fewer replacements and less maintenance over time.

Versatility Across Industries

Banana rollers are used in a variety of industries, including paper manufacturing, textile production, packaging, and more. The ability to customize the rollers means they can be adapted to different materials and processes, making them a versatile solution for many businesses.

Increased Product Quality

Whether you're manufacturing flexible packaging, printing materials, or textiles, maintaining the quality of the product is essential. A properly designed banana roller ensures that the material is processed without defects, resulting in a higher-quality finished product.

Why Choose the Right Banana Roller Supplier?

Choosing a reliable Banana Roller Supplier is essential to ensuring that you receive the highest quality rollers tailored to your specific needs. When evaluating potential suppliers, it’s important to consider several factors:

Experience and Expertise: A supplier with extensive experience in web handling systems will be able to provide valuable insights and recommendations for your production line.

Customization Capabilities: Not all suppliers offer customizable options, so it's important to work with a supplier who can tailor the roller design to your exact specifications.

Quality of Materials: The materials used in the construction of the banana roller will affect its performance and lifespan. Ensure that the supplier uses high-quality materials that match your needs.

Customer Support: A good supplier will provide ongoing support, from installation and adjustment to maintenance and troubleshooting.

Applications of Banana Rollers

Banana rollers are used in a wide range of applications across different industries, including:

Packaging: In flexible packaging lines, where precise web control is essential for consistent sealing, printing, and cutting.

Paper Industry: To keep paper smooth and aligned during printing, coating, or slitting processes.

Textile Industry: For preventing fabric wrinkling and ensuring even tension in dyeing and coating processes.

Printing: In high-speed printing lines where the material needs to be consistently aligned for accurate print placement.

Conclusion

Customizable banana rollers are an integral part of many industrial operations that rely on web handling systems. Whether you're processing plastic films, textiles, paper, or other materials, having a properly designed banana roller can greatly enhance your production efficiency and product quality. By choosing the right Banana Roller Supplier, you can ensure that your equipment meets the specific demands of your production line, leading to reduced downtime, fewer defects, and a more efficient manufacturing process.