Introduction

The Sea Water Magnesia Manufacturing Plant Project Report offers an insightful overview of setting up a facility dedicated to producing magnesia derived from seawater. Magnesia (MgO), also known as magnesium oxide, is a crucial industrial mineral used in a wide range of applications, including refractory materials, agriculture, environmental protection, and as a supplement in the food and pharmaceutical industries. Sea water contains a wealth of magnesium salts, which can be processed to extract magnesia, making seawater a cost-effective and abundant source.

This project report delves into the processes involved in setting up a Sea Water Magnesia manufacturing plant, including raw material sourcing, production processes, market trends, regulatory compliance, and financial considerations.

What is Sea Water Magnesia?

Sea water magnesia is magnesium oxide (MgO) that is produced by extracting magnesium salts from seawater. Magnesium is present in seawater as magnesium chloride (MgCl₂), which can be converted to magnesia through a series of chemical reactions.

Magnesium oxide has numerous uses across various industries, including:

- Refractories : Magnesia is used to manufacture high-temperature resistant bricks and linings for furnaces, kilns, and reactors.

- Agriculture : It is used as a fertilizer, particularly in soils that are deficient in magnesium.

- Environmental Protection : Magnesia is used for water treatment, including neutralizing acidic effluents and removing heavy metals.

- Pharmaceuticals : In some cases, magnesium oxide is used as an antacid or laxative in medical formulations.

- Construction : Used in the production of magnesium-based cement and building materials.

The process of extracting magnesia from seawater offers several advantages, such as the abundant availability of seawater and the relatively low cost of extraction compared to traditional mining of magnesium-bearing minerals.

Get a Free Sample Report with Table of Contents@

Market Demand and Growth Drivers

The global demand for magnesia is expected to grow steadily due to its versatile applications across multiple industries. Several key drivers are contributing to the increased demand for magnesia derived from seawater:

1. Increasing Demand for Refractory Materials

The demand for refractory materials, especially in the steel and cement industries, is a major driver for the magnesia market. Refractory bricks and linings made from magnesia are essential in high-temperature industrial processes such as steel production, glass manufacturing, and cement production.

2. Rising Agricultural Demand

Magnesium is an essential nutrient for plant growth. As the global population increases and the need for higher agricultural productivity rises, the demand for magnesium-based fertilizers is also growing. Sea water magnesia can be an efficient source of magnesium for this purpose.

3. Growing Environmental Regulations

Magnesia is used in various environmental applications, including water treatment and air pollution control. As environmental regulations become stricter, industries are increasingly using magnesium oxide for neutralizing acidic water, removing heavy metals, and controlling pollution from industrial waste.

4. Development of Green Technologies

There is growing interest in environmentally sustainable technologies. Magnesia derived from seawater offers an eco-friendly alternative to traditional mining methods of extracting magnesium. Furthermore, as industries shift towards greener production practices, the demand for eco-friendly magnesia will continue to rise.

5. Expansion of the Construction Industry

Magnesium-based cements and building materials are gaining popularity in the construction sector due to their environmental benefits and superior performance in specific applications, such as fire resistance and durability. This trend is expected to boost the demand for sea water magnesia in construction.

The Manufacturing Process of Sea Water Magnesia

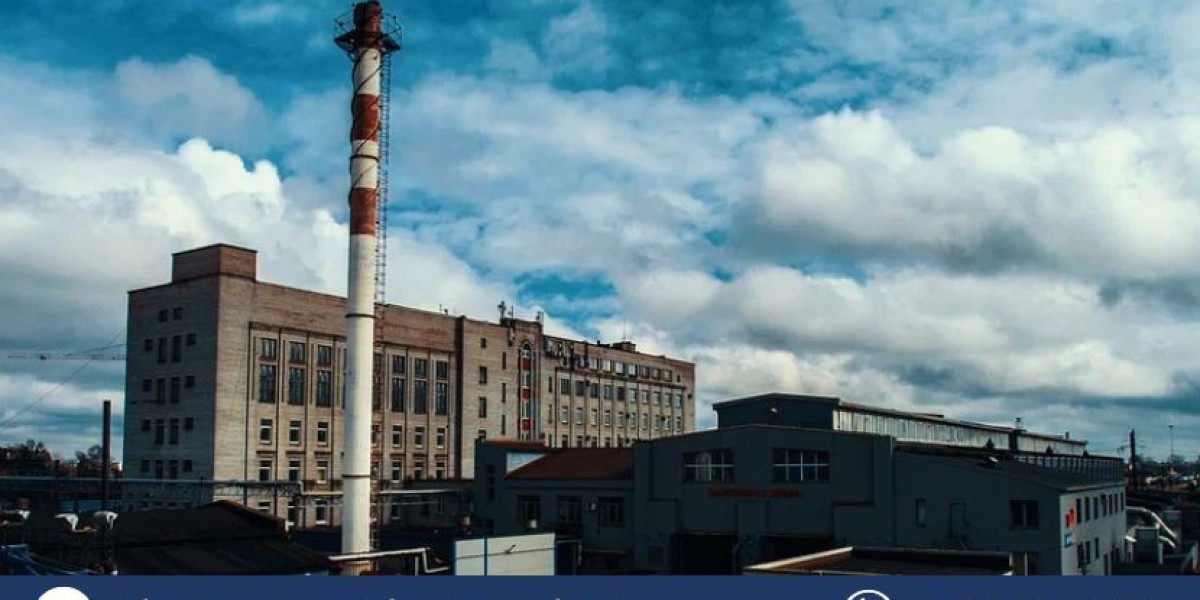

The production of magnesia from seawater is an environmentally sustainable process, as it uses seawater, which is an abundant and low-cost raw material. The extraction process generally involves several key stages:

1. Raw Material Sourcing

The primary raw material for magnesia production is seawater . Seawater contains approximately 0.13% magnesium chloride, which can be extracted and converted into magnesium oxide. The process starts with the collection of seawater and the precipitation of magnesium salts.

2. Precipitation of Magnesium Salts

Magnesium chloride (MgCl₂) is first separated from seawater through a precipitation process. This is typically done by adding calcium hydroxide (Ca(OH)₂) to seawater, which reacts with magnesium chloride to form magnesium hydroxide (Mg(OH)₂) .

3. Conversion to Magnesium Oxide

The magnesium hydroxide is then heated at high temperatures (around 1000°C to 1200°C) in a rotary kiln or furnace, where it undergoes calcination to form magnesium oxide (MgO). This reaction removes water from magnesium hydroxide and results in the production of magnesia.

4. Purification and Refining

After calcination, the magnesia is refined to remove impurities. The final product can be in the form of light-burned magnesia or dead-burned magnesia , depending on the temperature and conditions used during the calcination process. Light-burned magnesia is typically used in agriculture, while dead-burned magnesia is used in refractory applications.

5. Quality Control and Testing

The produced magnesia undergoes a series of quality control tests to ensure that it meets the required specifications for various industrial applications. These tests may include chemical analysis, particle size distribution, bulk density, and reactivity.

6. Packaging and Distribution

Once the magnesia is tested and approved, it is packaged in bags or bulk containers, depending on the intended use. It is then distributed to industries such as refractories, agriculture, environmental protection, and construction.

Key Considerations for Setting Up a Sea Water Magnesia Manufacturing Plant

1. Regulatory Compliance

The production of magnesia from seawater must adhere to local and international regulations regarding environmental protection, product safety, and quality control. Obtaining the necessary permits for water usage, waste disposal, and emissions control is critical to ensuring compliance with environmental laws.

2. Technology and Equipment

Setting up a sea water magnesia manufacturing plant requires specialized equipment, including:

- Seawater collection and filtration systems

- Precipitation tanks for separating magnesium salts

- Calcination kilns for converting magnesium hydroxide to magnesia

- Purification systems for removing impurities from the magnesia

Advanced technologies such as automation and real-time monitoring systems can enhance production efficiency and product quality.

3. Skilled Workforce

A skilled workforce is essential for the smooth operation of the plant. Employees should be trained in the chemical processes involved in magnesium extraction, safety protocols, and quality control measures. Additionally, a team of engineers and technicians is required to operate and maintain the equipment.

4. Sourcing Raw Materials

Seawater is the primary raw material, and it is important to establish a reliable supply of clean seawater with adequate magnesium content. The location of the manufacturing plant should be close to a source of seawater to minimize transportation costs.

5. Waste Management

The production of magnesia from seawater generates waste materials, including by-products such as calcium chloride (CaCl₂) and slurries of magnesium hydroxide. Proper waste management systems should be in place to handle these by-products and minimize environmental impact.

6. Cost and Financial Planning

Establishing a sea water magnesia manufacturing plant requires significant capital investment in infrastructure, equipment, and technology. It is essential to conduct a comprehensive financial analysis to estimate startup costs, operating expenses, and potential revenue. A sound business plan should also include strategies for reducing energy consumption and improving production efficiency to maximize profitability.

Market Outlook and Future Prospects

The global magnesia market is expected to grow due to the increasing demand for refractories, agricultural applications, and environmental technologies. As industries continue to prioritize eco-friendly and cost-effective materials, sea water magnesia will become an increasingly attractive alternative to traditional magnesium production methods. Key trends in the market include:

- Sustainability : Increasing focus on reducing the environmental impact of magnesium production will drive the adoption of seawater-based magnesia manufacturing.

- Refractories : The demand for high-quality magnesia for refractory applications in industries like steel and cement will continue to rise, driving growth in the magnesia market.

- Agricultural Growth : The need for high-quality fertilizers and soil amendments will increase demand for magnesia in agriculture.

- Global Infrastructure Development : As infrastructure development expands globally, particularly in emerging markets, the demand for construction materials such as magnesium-based cements will increase.

FAQ

1. What is Sea Water Magnesia?

Sea water magnesia is magnesium oxide produced by extracting magnesium salts from seawater. It is used in various industries, including refractories, agriculture, and environmental protection.

2. How is Sea Water Magnesia made?

Sea water magnesia is made by first extracting magnesium chloride from seawater and then converting it to magnesium oxide through a calcination process.

3. What are the applications of Sea Water Magnesia?

It is used in refractories, fertilizers, water treatment, air pollution control, and in the production of magnesium-based building materials.

4. What are the advantages of producing magnesia from seawater?

Seawater is an abundant, low-cost raw material, and producing magnesia from seawater is more sustainable compared to traditional mining methods.

5. What is the environmental impact of producing Sea Water Magnesia?

The environmental impact is generally low, especially if proper waste management and regulatory compliance are in place to handle by-products and emissions.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — USA

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Website: https://www.expertmarketresearch.com.au